High Pressure Injection System Accessory Syringe

HTSY® is a professional High Pressure Injection System Accessory Syringe factory.HTSY® is one of the earliest high-tech enterprises recognized by the government in Tianjin, China. We have a professional R&D team dedicated to the research and development and production of various high-pressure syringes and their matching consumables, providing high-quality and precise products to customers worldwide. Welcome your inquiries.

Send Inquiry

HTSY® is High Pressure Injection System Accessory Syringe manufacturer from China.The company has a strong production capacity and production lines, and is capable of providing customers with high-quality and reasonably priced products. Meanwhile, we have multiple mature logistics channels and are equipped with 24-hour human customer service to provide customers with all-round, high-quality and considerate services.

Ultimate compatibility to ensure injection stability

It is precisely matched with high-pressure syringes. The syringe interface adopts a dedicated sealing design to eliminate the risk of leakage and tube disconnection under high pressure, ensuring that contrast agents and other liquid drugs are accurately pushed at the preset flow rate and dosage, and avoiding diagnosis and treatment errors caused by equipment incompatibility.

The fit between the inner wall of the syringe and the push rod has been precisely calibrated, ensuring a smooth injection process without any jamming. Combined with the intelligent pressure feedback system of the syringe, it can effectively reduce the fluctuation of injection resistance, guaranteeing the stability and controllability of the injection process.

Safety protection reduces the dual risks for both doctors and patients

Medical-grade material: The main body of the syringe is made of medical-grade polypropylene (PP) or polycarbonate (PC) material, which has high biocompatibility, no allergenicity, and is resistant to corrosion by common drug solutions such as contrast agents and physiological saline, eliminating the potential impact of material leachates on patients.

Disposable sterile design: Sterilized with ethylene oxide upon leaving the factory, independently packaged, and ready for use upon opening without the need for additional sterilization processes. This not only meets the requirements of hospital infection control but also saves the disinfection costs and time for departments.

Product Parameter(Specification)

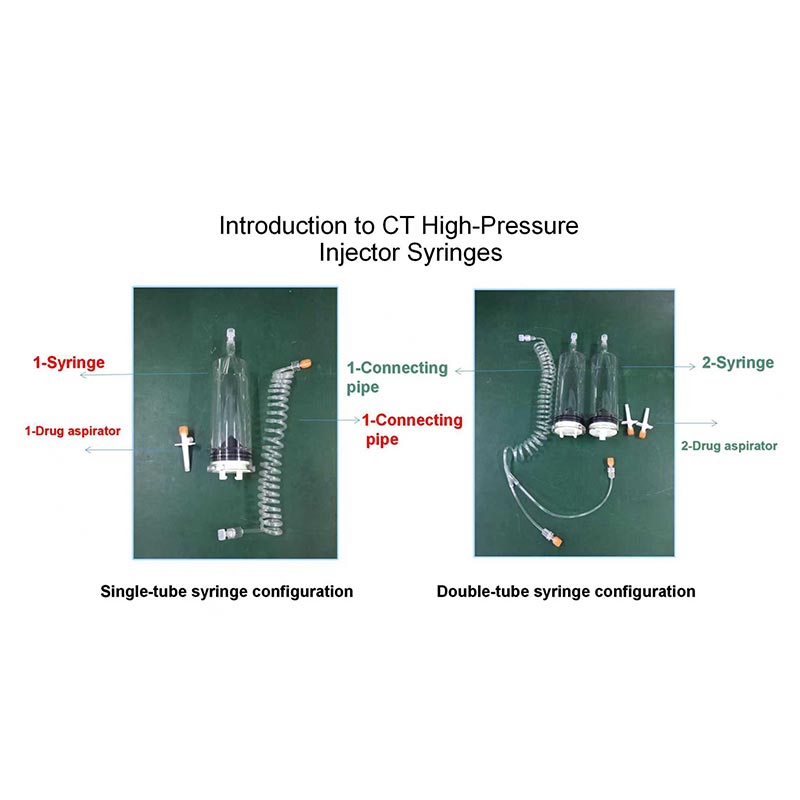

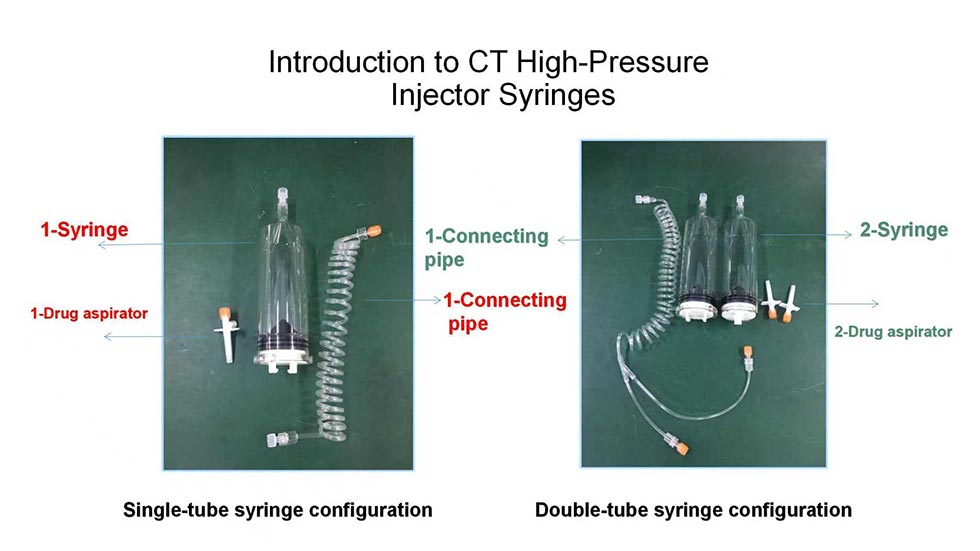

| Model | Configuration | Packaging |

| 1 | Configuration: 1-200ml syringes, 1-puncture suction tubes, 1-180cm single-channel connecting tubes | 50 pieces per piece;Outer box dimensions: 57.5*37.5*41, gross weight: 11kgs |

| 2 | Configuration: 2-200ml syringe, 2-puncture aspirator, 1-200cm multi-channel connecting tube (two check valves) | 30 sets/pieces; Outer box dimensions: 57*46*41.5 cm, gross weight: 12kgs |

| 3 | Configuration: 1-150ml syringe, 1-J type suction tube, individually packaged 120cm single connection pipe (pressure resistance 600psi) | 60 pieces per piece; Outer box dimensions: 57.5*31.5*42.5 cm, gross weight: 12kgs |

Usage Tutorial

The following is the operation method for High Pressure Injection System Accessory Syringe

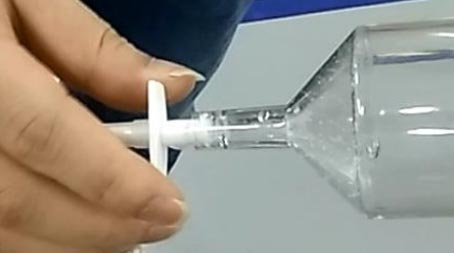

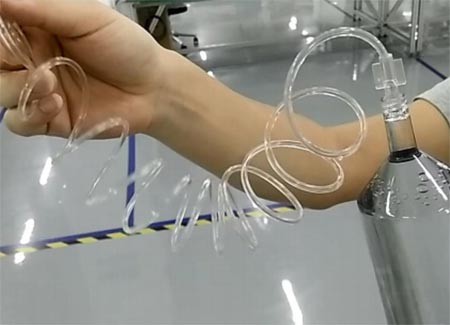

1.Install the syringe

2.Expel the air from the syringe

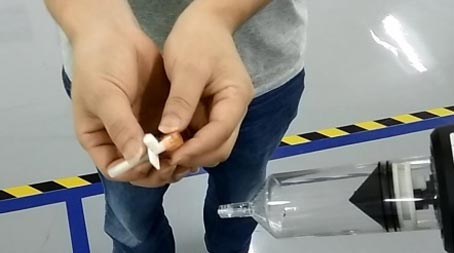

3.Connect the puncture aspirator

4.The puncture aspirator rotates clockwise

5.Lift the injection head, puncture the aspirator, insert the medicine bottle and start aspirating the medicine

6.After the drug aspiration is completed, remove the aspirator, replace the connecting tube and exhaust the air. Then, the injection can be administered to the patient