DSA High Pressure Injection System

HTSY® is a professional DSA High Pressure Injection System factory.HTSY® is one of the earliest high-tech enterprises recognized by the government in Tianjin, China. It is one of the earliest high-tech enterprises recognized by the Chinese government. HTSY® has a professional R&D team dedicated to the research and development and production of various high-pressure injection systems, so we can provide safe and precise high-pressure injection equipment. Welcome to contact us!

Send Inquiry

HTSY® is DSA High Pressure Injection System factory manufacturer from China.Our company has strong production capacity and standardized production lines, and is capable of providing customers with high-quality and reasonably priced products. At present, the company has established branches and offices in many places around the world, building a complete sales network and after-sales maintenance system. Meanwhile, we have multiple mature logistics channels and are equipped with 24-hour human customer service, which can provide customers with high-quality and considerate services in all aspects.

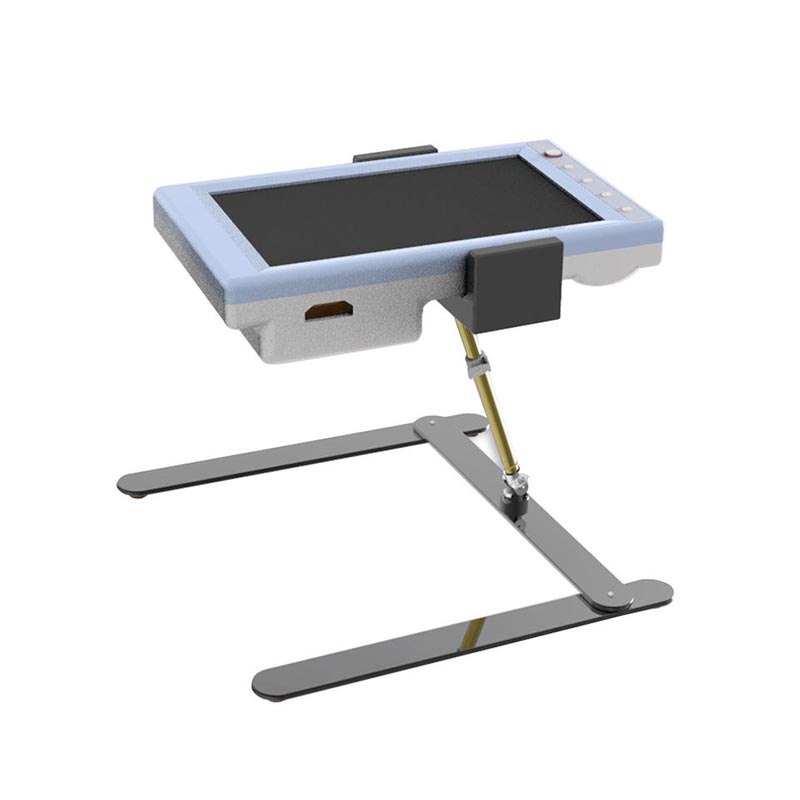

The DSA high pressure injection system(AnGio D200) is exquisitely designed and rationally adopts a streamlined structure designed by ergonomics, making the operation more convenient. Equipped with multiple security protection schemes, it makes use more reassuring. The precise electromechanical control system ensures more stable injection. The random application of injection plans and multi-stage Settings make the imaging clearer.

Injection head

-The nose of the aircraft features smooth lines, a robot-style design with a strong sense of technology, and a friendly color.

-Silicone rubber keys, wear-resistant and dirt-resistant, with a reasonable layout, can freely control the operation of the equipment. At the same time, it is equipped with a manual boost knob to achieve micro-dose trial injection.

-The syringe protection sleeve can be installed synchronously and has an automatic position detection function.

-The injection head is equipped with an Angle recognition function, which can automatically identify the exhaust position and the injection position. When there is no injection position, the system cannot activate the injection plan.

Floor-standing brackets and electronic control

- Integrated safety stand, 240° rotation direction, suitable for various operating room layouts, with a built-in protective case storage platform for more convenient use;

- The circular design of the electrical control box on the runway makes the body more exquisite. The carefully designed heat dissipation system makes the heat dissipation more artistic and diversified.

The functional modular design is reasonable in layout and convenient to operate. It can guide the operation process in real time with text to avoid misoperation.

The system is equipped with 100 sets of contrast injection schemes to choose from.

-10-stage setting, reasonable planning of injection operation guidance, safe and efficient;

-Injection progress bar, updated in real time;

-Real-time pressure value and curve graph display;

- Over 1,000 injection history records stored;

Product Parameter(Specification)

| No. | Technical features | Description |

| 1. | Syringe volume capacity range | 1~150mL, step 1ml/s |

| 2. | Injection speed rate |

Normal mode:0.1~50mL/s,step 0.1mL/s,step 0.1mL/s low-speed mode:1-59ml/min,step 1mL/min |

| 3. | Auto-fill speed rate range | 1~150mL, step 1ml/s |

| 4. | Air expelling speed rate range | 1~10mL/s,step1 mL/s |

| 5. | Injector head rotation angle | Horizontal rotation angle 240° |

| 6. | Auto fill, auto air exhaust | Provided |

| 7. | Audible and visual alarm for over pressure | Provided |

| 8. | *Syringe temperature retainers | Provided |

| 9. | Pressure setting range | 10~1200psi,step 1psi |

| 10. | Automatic optimization of pressure limit values | Provided |

| 11. | Real-time pressure-time graph display | Provided |

| 12. | Injection delay | 0~9999s, step 1s |

| 13. | Scan delay | 0~9999s, step 1s |

| 14. | Phased delay | 0~9999s, step 1s |

| 15. | Phased injection | 10 phases to ensure enhanced results |

| 16. | Injection protocol | 1000 protocols |

| 17. | Test injection function | 1-5mL, step 1mL |

| 18. | Air exhausted confirmation function | Provided |

| 19. | Injection history review function | Provided |

| 20. | System self-test and error display | Provided |

| 21. | Power of Input | 800 VA |

Product Feature And Application

1. Equipped with a low-speed injection mode: 0.1-50ml/m, with an increment of 0.1 ml/m (single ml/m)

2. It has the function of detecting the installation of the syringe protection sleeve: identifying the syringe when it is installed in place to ensure reliability.

3. Have user access permission function: Password authentication is required to obtain the permission to access the injection history.

4. The minimum pressure value is ≤ 10psi, the maximum pressure value is ≥ 1200 PSI, the increment is 1psi, and the real-time pressure curve is displayed.

5. This DSA High Pressure Injection System has a scanning delay prompt function: it will give prompts during the countdown of 10 seconds and 5 seconds

6. The maximum scanning delay, injection delay and stage delay can reach up to 9999 seconds.

7. Up to 10 stages of injection are available, meeting the scanning requirements of various complex cases.

8. The most powerful after-sales service system: After-sales service points are set up in the provincial capital cities of each province, providing the most powerful after-sales service system.

Production Details

| Component Name | Quantity |

| Monolithic rack | 1 |

| Single barrel injection head | 1 |

| Electric cabinet | 1 |

| Proximal touch screen | 1 |

| Syringe sheath | 1 |

| Foot pedal | 1 |

| Disposable high-pressure contrast injector syringe set | 5 |